FabRobotics: The Fusion of 3D Printing and Mobile Robots

3D printing has greatly expanded our capacity to make and customize personal objects. Need a pencil holder? 3D print one! Playing Dungeons and Dragons and you want a figurine of your own character? You could make it yourself too. Whether at home, in classrooms or in research fields, they have become increasingly affordable, accessible, and more widely researched than ever before. However, their technical capabilities are often limited by the length of time required, or the use of extra materials to create support structures when printing an overhang.

A collaboration between the University of Chicago Department of Computer Science’s Actuated Experience Lab (AxLab), and the Massachusetts Institute of Technology Computer Science and Artificial Intelligence Laboratory’s Human-Computer Interaction (HCI) Engineering Group sought to address these issues and further advance fabrication and interaction when they combined 3D printing technology with mobile robots.

“My lab has been exploring the development of novel user experiences with mobile robots such as HERMITS and AeroRigUI,” Assistant Professor of Computer Science and AxLab PI Ken Nakagaki stated. “We placed different 3D-printed ‘shells’ onto these robots to expand and customize their interaction capability. Through these explorations, the idea of ‘what if robots’ ‘shells’ could be actively and adaptively overwritten by 3D printers naturally came up. As the HCI Engineering group at MIT is the top leading lab in the world for making novel fabrication systems, one of their PhD candidates, Martin Nissar, and I shared an interest in fusing robotics and fabrication to pursue this project idea.”

Undergraduate senior at UChicago, Ramarko Bhattacharya, Carnegie-Mellon University student and 2023 DSI Summer Lab participant Jonathan Lindstrom, and MIT student researcher Ahmad Taka came together to research what was later coined as FabRobotics — a digital fabrication pipeline which aims to create new opportunities for 3D printers to fabricate objects quickly and efficiently, and for mobile robots to enhance their adaptability and interactivity.

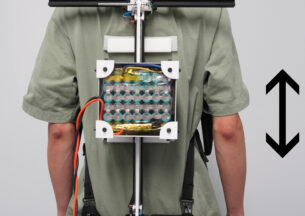

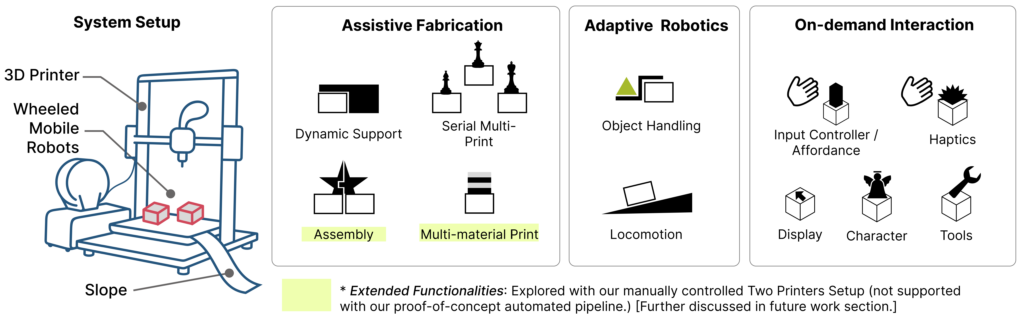

In their paper titled, “FabRobotics: Fusing 3D Printing with Mobile Robots to Advance Fabrication, Robotics, and Interaction”, the researchers explore the possibilities and opportunities of merging the capabilities of 3D printing technology with that of current mobile robot technology. They accomplished this by grafting control of mobile robots into the 3D printing process, which enables for three main benefits. They show that FabRobotics enables Assistive Fabrication, where the workflow of the 3D printing process is made more seamless, saving time and production cost; they also demonstrate Adaptive Robotics, as the mobile robots can be constantly modified to suit the user’s needs based on 3D printing additional features; they also show On-demand Interface, in which the uniquely hybrid control setup allows for users to direct both the FabRobotics 3D printer’s fabrication and the robot’s locomotion capabilities for tangible interactions.

“I hope this research can be used as a foundation for advancing the capabilities of how 3D prints can be deployed on demand,” Bhattacharya commented. “While there are limitations, the possibilities are endless once we have more advanced fabrication techniques and robots. Our system allows for on-demand fabricated artifacts. Imagine having the ability to have mini-figurines or toys pop up on your desk whenever you feel like it, or having a mini-robot that can modify itself for whatever task it has to do. The possibilities are endless and super exciting!”

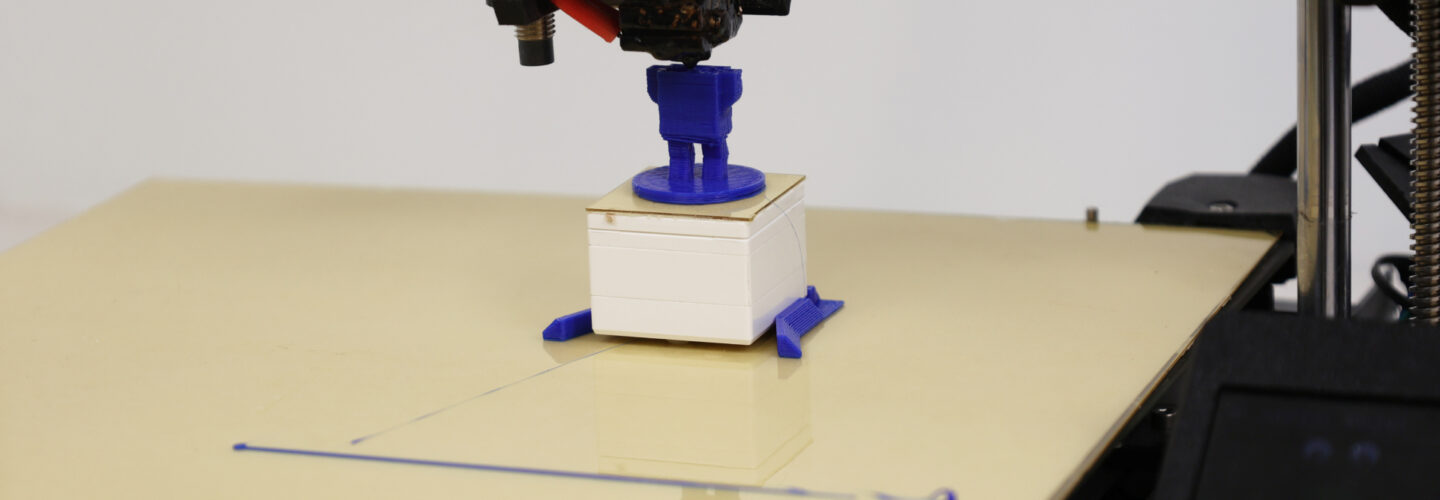

Ultimately, FabRobotics is a control architecture that is able to mediate interactions between both 3D printers and mobile robots. In their lab, the setup consisted of one 3D printer, multiple tabletop robots, and a slope attached to the printer bed which enabled the robots to travel in and out of the print beds on their own. The team demonstrated many uses for these mobile robots. These include being dynamic support structures, assisting in assembling objects that need to be combined from disjoint parts, or modifying the robot’s object handling abilities.

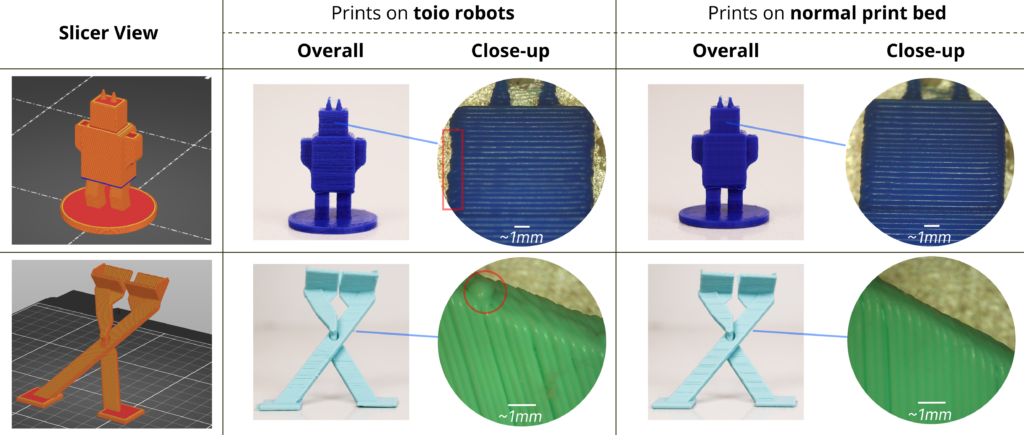

One thing the authors noticed when working with the robots is that the print quality appears to be slightly lower with mobile robots than without. In a close-up figure of a printed avatar, the edges of the figure appear to be slightly jagged and uneven when printed on a mobile robot, unlike the quality when printed directly on a print bed.

One thing the authors noticed when working with the robots is that the print quality appears to be slightly lower with mobile robots than without. In a close-up figure of a printed avatar, the edges of the figure appear to be slightly jagged and uneven when printed on a mobile robot, unlike the quality when printed directly on a print bed.

Although there are still a few limitations to the current model, there are many avenues for further exploration. Beyond what they were able to accomplish with just one printer and two robots, the team hopes to be able to greatly expand the capacity of this system by incorporating more robots and more 3D printers into the system. In addition, they hope that they can automate other aspects of the process, such as the removal of delivered 3D printed objects from the robots, as well as including charging docks, so that during longer prints, multiple robots can hand off to each other in order to make the printing experience more seamless. Even with the capabilities the system has now, FabRobotics is able to seamlessly print and deliver Dungeon and Dragons characters during gameplay and implement personalized and tangible calendar reminders throughout the day to enhance productivity.

When asked about the vision they had for FabRobotics, Nakagaki stated, “I’m personally excited about the future opportunities where 3D printers become part of the interaction devices. Rather than just 3D printing static objects, FabRobotics opens up a way to flexibly and adaptively print objects that can dynamically move, come out of the print beds, and interact with users. As 3D printing technologies are advancing day by day (some researchers are developing super fast fabrication techniques), our research of fusing tabletop mobile robots and 3D printers layout immense opportunities to bring functional, robotic objects to users’ hands for entertainment/storytelling, or assistive technologies.”

Ultimately, the incorporation of mobile robots into 3D printing is a first step toward fusing two rapidly evolving technologies to leverage the unique advantages of each and open up new avenues across both areas. The team just recently presented their work in the 18th International Conference on Tangible Embedded and Embodied Interaction (TEI2024), and are looking forward to further developing their prototype. To learn more about the world of FabRobotics and the team behind it, please visit the AxLab lab page.