CS/MADD Center Workshop Introduces DIY Soft, Stretchable Electronics

The future of technology is stretchable. Many promising innovations, such as soft robotics, advanced wearable devices, and a broader wave of “smart” products for consumers and industry, are held back by the inherent rigidity of circuit boards, wiring, and electronic components. To make these technologies feasible, electronic circuits need to take a cue from yoga and learn how to stretch it out.

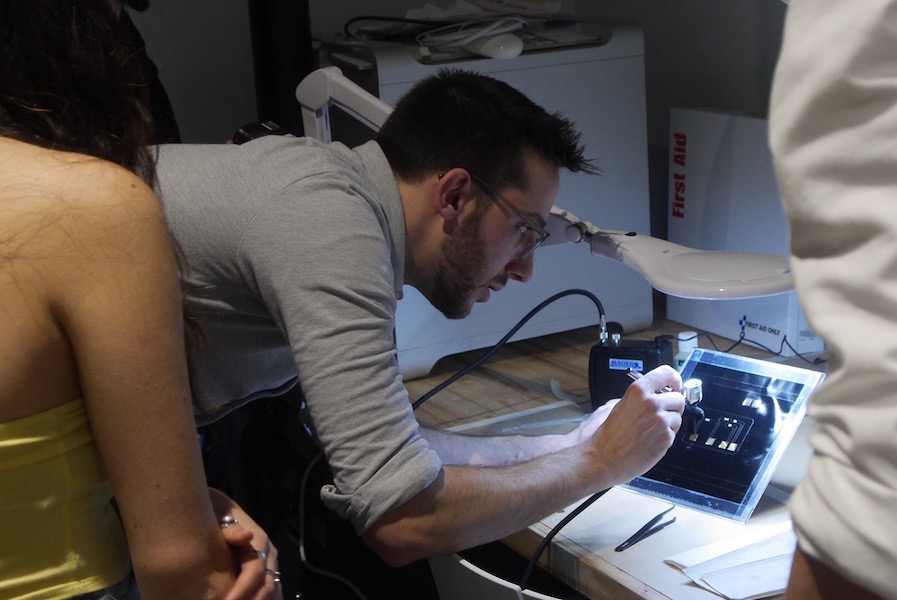

On March 12, a workshop in the new Media Arts, Data and Design (MADD) Center in John Crerar Library taught students a DIY (do it yourself) method for making stretchable electronics with silicone and liquid metal. Led by visiting student Steven Nagels, a graduate student from Belgium working with UChicago CS Assistant Professor Pedro Lopes, the tutorial combined material science and makerspace methods to enable exciting new wearables and other inventions.

“We want to hand our method over to the human-computer interaction (HCI) researchers, the people who will actually be able to explore what we can do on the skin,” Nagels said. “We think it will inspire people a little bit to give them the idea of ‘if I'm good at making these kinds of devices, I will be able to do all these cool studies, create novel hardware which was not there before, etc!’”

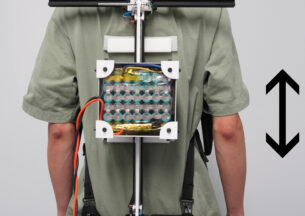

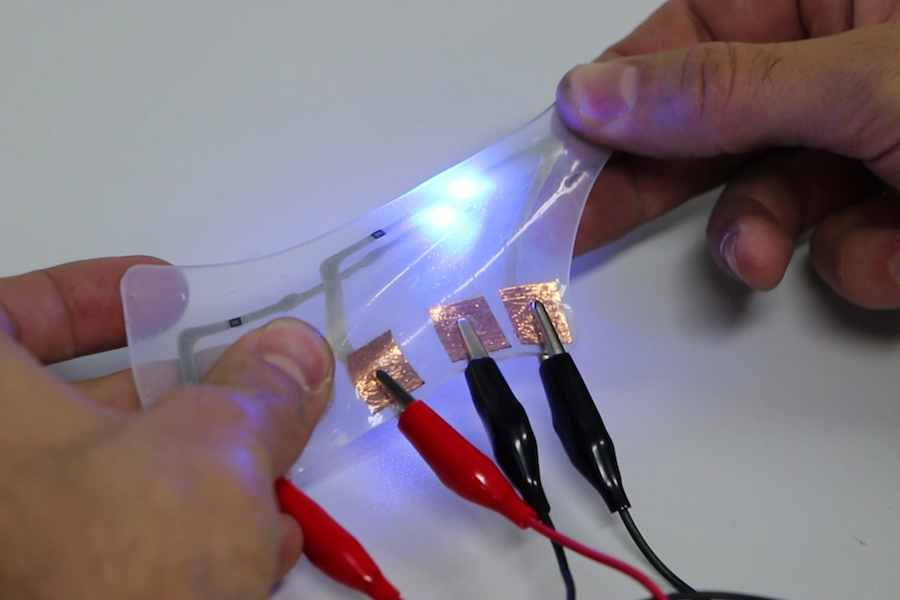

Nagel developed the Silicone Devices project as part of his graduate studies program at Hasselt University in Belgium. The idea expands upon the “flexible” electronics currently hitting the market through phones with foldable screens and solar panels that bend to fit rounded surfaces. But Nagels’ devices go further than flexible, allowing circuits to be repeatedly stretched up to double their original size with no damage or loss of performance.

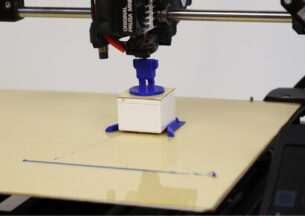

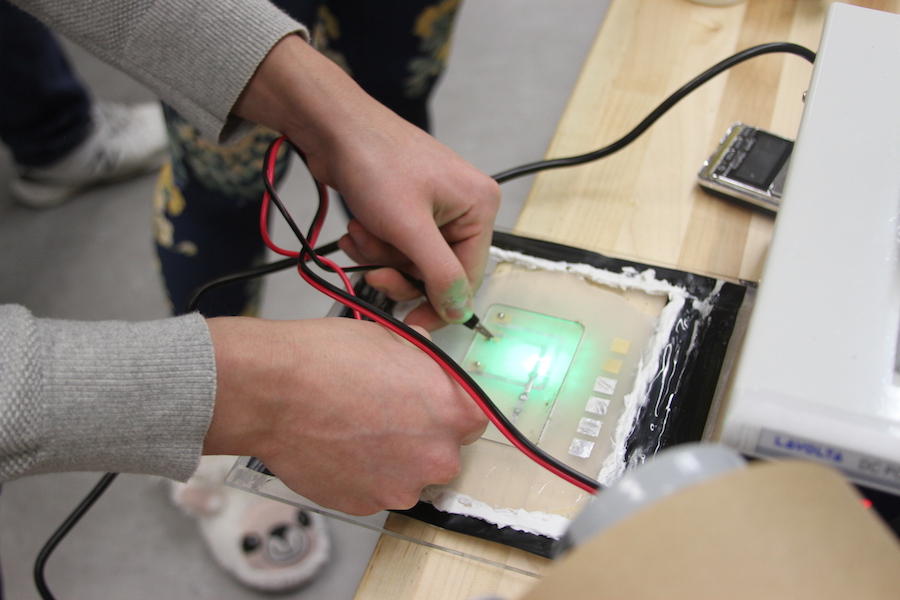

The method relies upon two key materials: casting silicone for the and a metal that is liquid at room temperature for the connections. Using off-the-shelf electronic components and the type of laser cutter often found in makerspace facilities (such as MADD’s Hack Arts Lab), people can create stretchable versions of an Arduino microcontroller, a wired-up wristband, or even electronic “skin.”

These e-skin applications have been proposed by industry for everything from making more sensitive factory robots to designing comfortable medical devices, such as an insulin meter, that can be worn for long periods of time, Nagels said. By making the fabrication as easy to perform as possible, he hopes that makers and inventors will come up with even more uses and HCI researchers will start studying how stretchable devices change the way we use technology in our everyday lives.

In the four-hour workshop, participants constructed their own multi-layered showcase circuit. The workshop accompanied Lopes’ Winter 2019 Emerging Interface Technologies course (aka “HCI Topics”).

Photos by Jas Brooks, Pedro Lopes, and Rob Mitchum.